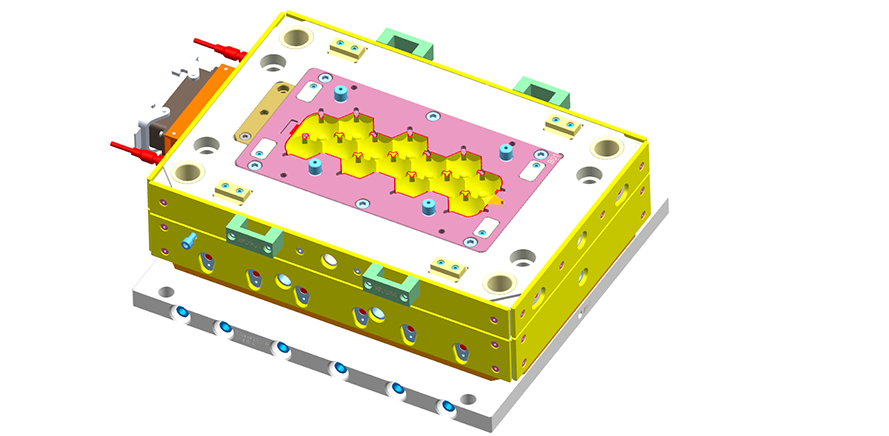

Mold Design

Our engineering team has over 20 years of experience in designing and manufacturing various silicone molds, including LSR cold runner injection molds, LSR hot runner injection molds, two-part silicone molds, overmolded molds, solid silicone vacuum hot press molds, and cold press molds. We are skilled in using various 2D and 3D software for mold design and mold flow analysis software. Our mold body design follows the basic standards of HASCO&MISUMI to ensure quality and productivity while keeping the product design-oriented. We pay attention to details in our mold design to guarantee the highest quality and productivity. Our team is familiar with various mold structures and techniques to optimize the manufacturing process. We are committed to providing our clients with the best possible service and producing top-quality silicone molds that meet their specific needs.