Nov. 12, 2025

The Ultimate Guide to Silicone Light Guide Lenses

What is Silicone Light Guide Lens?

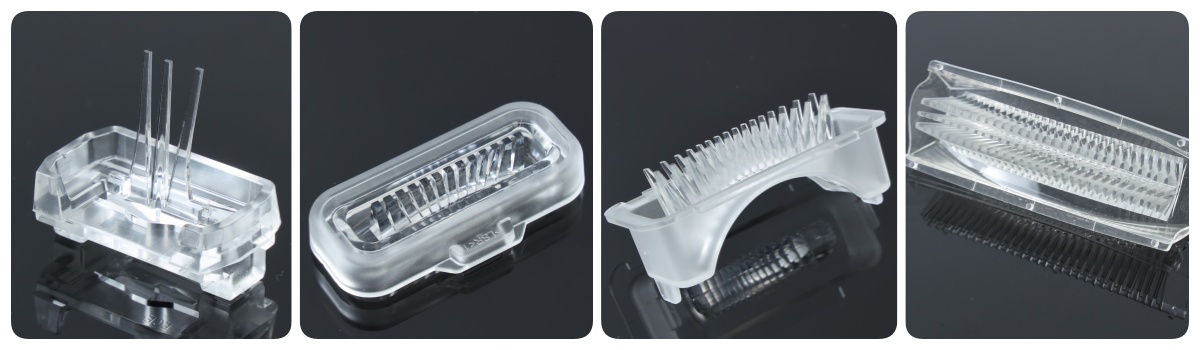

Silicone light guide lenses, also known as silicone condensers or silicone collimators, are high-precision optical components made from optical-grade liquid silicone rubber (Optical LSR) through liquid injection molding (LIM). They are widely used for guiding, focusing, or distributing light in LED lighting, automotive headlights, and backlight illumination systems.

These lenses combine the light transmission function of a light guide column with the optical shaping capabilities of a precision lens. With features such as high temperature resistance, excellent optical transparency, UV stability, and anti-yellowing performance, silicone light guide lenses provide efficient light control and long-term durability in demanding environments.

Structure and Working Principle of Silicone Light Guide Lenses

A silicone light guide lens usually has a columnar structure with optical features such as micro grooves, reflective surfaces, and refractive geometries. It works by utilizing the total internal reflection and refraction properties of silicone to efficiently guide, focus, or diffuse light from LEDs or other sources toward a targeted direction. This design ensures precise light distribution and high transmission efficiency.

Key Advantages of Silicone Light Guide Lenses

1. Superior Light Efficiency: Achieves uniform and spot-free illumination, improving the visual quality and appearance of lighting products.

2. Excellent Flexibility: Soft, compressible, and form-fitting to LED modules and housings, offering dustproof and waterproof performance.

3. Wide Temperature Range: Reliable operation from -40°C to +150°C, ideal for automotive and outdoor applications.

4. Anti-UV and Aging Resistance: Maintains high light transmittance and optical stability even after long-term use.

5. Flexible Design Options: Can be molded into various shapes (round, square, or custom) and support long-distance light transmission.

YEJIA Answers 5 Common Questions About Silicone Light Guide Lenses

To help customers better understand silicone optical components, YEJIA provides in-depth answers to five key questions about silicone light guide lenses:

1. Can Silicone Light Guide Lenses Be Made from Regular High-Transparency Silicone?

YEJIA's Answer: Not recommended, and generally not feasible.

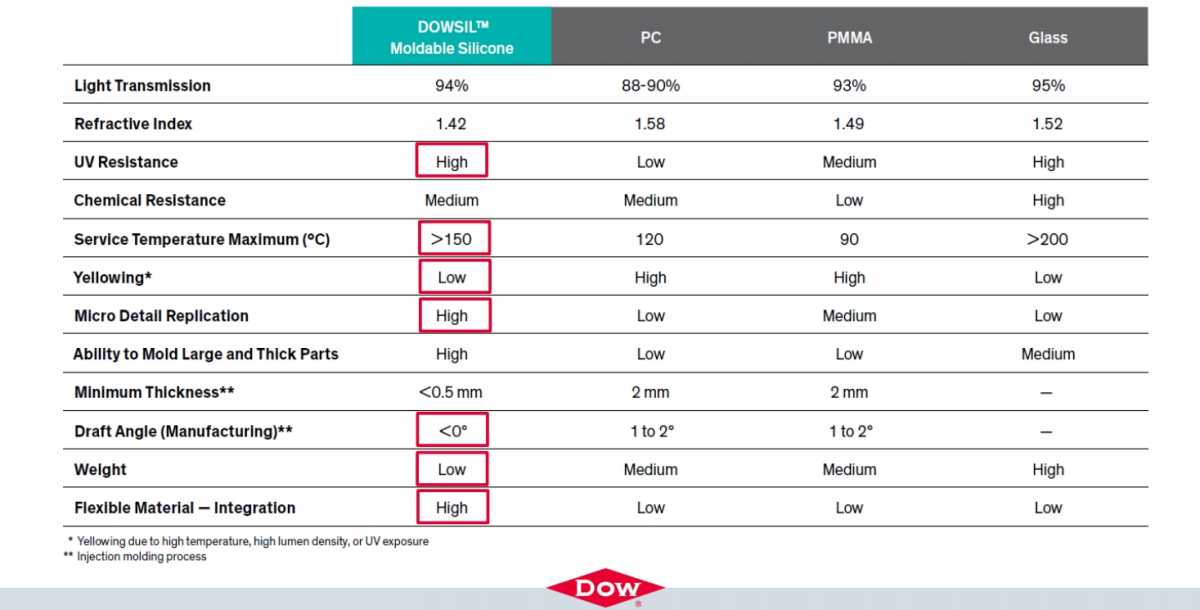

Standard silicone materials lack the optical clarity, refractive stability, and UV resistance required for precision optics. This can lead to uneven light spots, optical loss, and molding defects. Only optical-grade LSR materials—such as Dow Corning MS-1002/4002, Wacker, or Momentive—can meet these demanding requirements. YEJIA works closely with each client's R&D team to select the best material that balances optical performance and cost efficiency.

2. Can Optical Silicone Lenses Be Produced with Regular Equipment?

YEJIA's Answer: No.

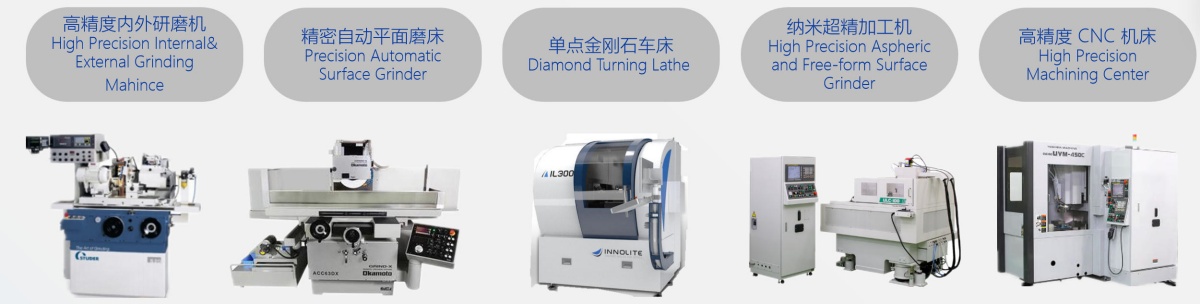

Silicone light guide lenses are high-precision optical components, requiring tight control over injection accuracy, temperature stability, and mold alignment. Standard silicone molding machines often cannot achieve the surface polish or dimensional precision needed for optical applications.

At YEJIA, we use dedicated LSR injection molding systems, paired with high-precision optical molds, to ensure consistent optical quality and dimensional accuracy. This is one of the main reasons why tooling and product prices differ significantly among suppliers.

3. Why Do Mold Costs for Silicone Light Guide Lenses Differ Greatly?

YEJIA's Answer:

Mold costs depend on precision tolerance, optical surface finishing, structural complexity, lens size, and the supplier's manufacturing capability. High-quality optical molds require ultra-precision machining and mirror polishing, both of which involve significant equipment investment and process expertise.

4. Why Do Prices Vary for the Same 3D Lens Design?

YEJIA's Answer:

Even with identical 3D drawings, prices differ because manufacturers interpret optical precision, functionality, and testing standards differently. Factors such as material grade, mold quality, process complexity, yield control, and testing methods all impact cost.

Some suppliers only ensure basic transparency, while others, like YEJIA, conduct comprehensive optical inspections to verify 3D geometry, 2D dimensions, and optical performance before shipment.

5. Material Selection and Supplier Evaluation for Silicone Light Guide Lenses?

YEJIA's Answer:

Selecting the right material requires evaluating light transmittance, refractive index, thermal stability, and UV resistance. Meanwhile, supplier assessment should consider batch consistency, certifications, supply capability, and technical support. YEJIA started with automotive optical silicone lenses, where quality requirements are extremely high. Today, our silicone optical components are also used in consumer electronics, commercial lighting, and general illumination. We verify every material's feasibility based on product requirements to ensure optimal performance at a competitive cost.

YEJIA also supports the localization of optical-grade silicone materials in China—promoting innovation, reliability, and cost efficiency across the silicone optics industry.

Stay Tuned

For more professional insights on silicone light guide lenses, stay tuned for upcoming technical articles from YEJIA.