Dec. 18, 2025

In today's world of precision consumer products, it is often the smallest components that determine the overall user experience. The silicone cross slit valve is one such component—a quiet yet critical "guardian" hidden inside the cap. From sports water bottles and condiment packaging to personal care products and medical containers, its performance directly impacts leak prevention, dispensing control, and product safety.

While many cross slit valves may look similar at first glance, their quality can vary significantly. Understanding how to distinguish a high-performance valve from a low-quality alternative is essential. This article provides a systematic overview of silicone cross slit valves and a practical, professional guide to evaluating their quality.

Core Understanding: What Is a Silicone Cross Slit Valve?

A silicone cross slit valve is a one-way dispensing valve made from high-transparency liquid silicone rubber (LSR), featuring a precisely engineered cross-shaped slit at its center. Its core function is simple yet highly effective: liquid is dispensed when pressure is applied, and the valve seals instantly once the pressure is released.

Integrated into caps or valve housings, the valve relies on the inherent elasticity of silicone combined with precise slit geometry to control flow and prevent leakage. As a result, it has become an indispensable component in modern squeeze-type packaging solutions.

Why Silicone Cross Slit Valves Are Essential Components?

High-quality silicone cross slit valves are often described as "intelligent anti-leak valves" due to their outstanding performance characteristics:

1. Controlled dispensing: Enables consistent, measurable flow without splashing or side spraying.

2. Reliable sealing: The cross-slit structure forms multiple sealing lines when closed, effectively preventing liquid or air leakage.

3. Wide temperature resistance: Maintains stable performance from approximately -40°C to 200°C.

4. Long-term elasticity: Excellent resilience and fatigue resistance ensure rapid recovery even after prolonged use.

5. Easy integration: Standardized designs allow seamless installation into a wide range of standard or custom bottle caps.

Application Scenarios: Where Are Cross Slit Valves Used?

Silicone cross slit valves are widely applied in products that require clean, convenient, and leak-proof dispensing, including:

◆ Food and beverage packaging: Honey, ketchup, salad dressings, syrups, sauces, and concentrated juices

◆ Home and personal care: Shampoo, body wash, hand soap, dishwashing liquid

◆ Cosmetics and skincare: Facial cleansers, lotions, creams, and serums in squeeze packaging

◆ Medical and laboratory use: Reagent bottles, disinfectant containers, and controlled-flow or one-way venting systems.

As consumer expectations for safety and usability continue to rise, the application scope of silicone cross slit valves continues to expand.

9 Key Criteria for Evaluating Silicone Cross Slit Valve Quality

Assessing valve quality requires a comprehensive evaluation covering materials, manufacturing processes, appearance, and real-world performance:

Raw material quality

Premium valves are made from food-grade or medical-grade high-transparency LSR. Inferior products often use ordinary silicone with reduced clarity and durability.

Manufacturing process

LSR injection molding ensures high precision, cleanliness, and batch-to-batch consistency. Traditional compression molding often leads to dimensional inconsistency, misaligned slits, and surface defects.

Transparency Clear Color

High-quality valves appear clear and transparent. A cloudy or milky appearance usually indicates lower material purity.

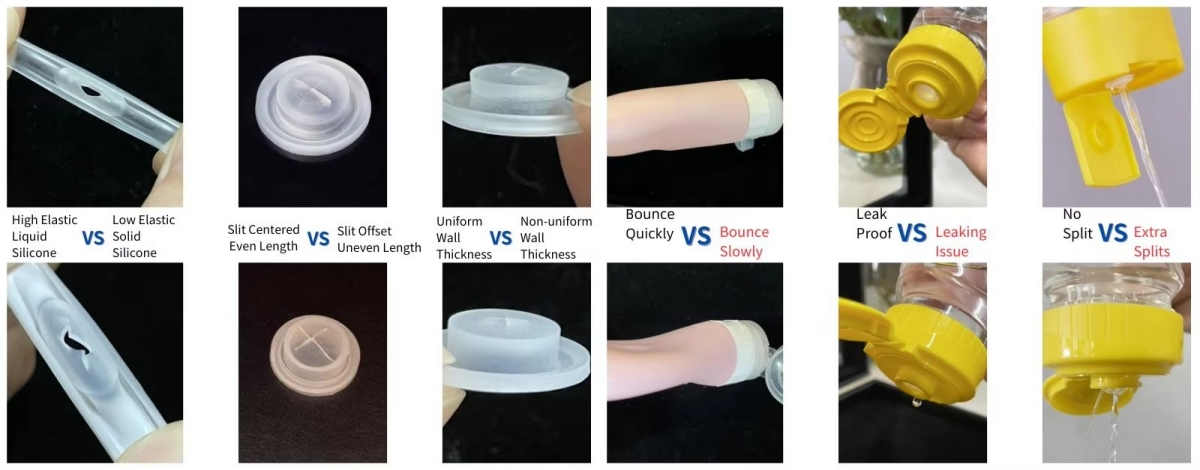

Stretch performance

When stretched, premium silicone remains transparent and elastic. Low-quality silicone tends to whiten, signaling weak tear resistance and faster aging.

Surface finish

A quality valve has a smooth surface free of black spots, haze, bubbles, or impurities. Even minor defects can compromise sealing performance.

Elastic recovery

High-grade silicone rebounds quickly and maintains elasticity after repeated compression. Poor-quality valves recover slowly and harden over time.

Cross-slit precision

The slit is the functional core. It must be centered, uniform in length and angle, cleanly cut, and free of burrs, with tight tolerance control (typically within ±0.3 mm) to ensure smooth opening and secure sealing.

Dimensional consistency

Reliable manufacturing delivers minimal color variation, tight dimensional tolerances (e.g., ±0.2 mm), and precise cap matching—essential for automated assembly and long-term reliability.

Functional performance testing

Ultimately, performance defines quality. A premium valve must pass inverted leak tests, provide stable and repeatable flow, maintain a concentrated dispensing angle (for example, within ±15°), avoid flow splitting, and achieve fast rebound times (as low as 0.3 seconds).

YEJIA: Manufacturing Excellence You Can Rely On

With more than a decade of industry experience, YEJIA has established a strong reputation for producing high-quality silicone cross slit valves through the following core strengths:

★ Certified materials

All products are made from FDA- and LFGB-compliant food-grade or medical-grade high-transparency LSR, ensuring safety and consistent performance from the source.

★ Advanced manufacturing

Fully automated LSR injection molding lines operate in Class 100,000 cleanroom environments, delivering exceptional precision, cleanliness, and consistency.

★ Technical expertise

In-house mold design and proprietary cross-slit cutting technology ensure industry-leading slit accuracy and uniformity, guaranteeing stable flow control and reliable leak prevention.

★ Comprehensive certifications

The factory is certified to ISO 9001, ISO 13485 (medical devices), and IATF 16949 standards. Products comply with FDA, LFGB, and EU food contact regulations.

★ Proven market performance

YEJIA silicone cross slit valves are trusted by well-known brands worldwide and have been validated across demanding applications in food, personal care, and medical industries.

Make Precision Dispensing and Leak Prevention a Standard Feature of Your Product

Choosing a high-quality silicone cross slit valve is not just a component decision—it is an investment in user experience, product reliability, and brand reputation.

At YEJIA, we provide complete silicone valve solutions, from design support and prototyping to stable mass production. We believe that truly reliable sealing is achieved through uncompromising attention to detail.

Contact us today to request samples or discuss custom solutions—and ensure that every squeeze performs with precision, consistency, and confidence.