Jul. 14, 2025

Medical Silicone Products Introduction

In today's fast-evolving medical technology landscape, medical silicone products have become essential components in the healthcare field due to their superior performance and diverse applications. This article will explore the definition, production process, and application areas of medical silicone products, highlighting the exceptional advantages of YEJIA in producing medical grade silicone products.

1. What Are Medical Silicone Products?

Medical silicone products are items made from silicone materials that adhere to strict medical standards. These products are designed for use in medical devices, consumables, and applications that come into direct or indirect contact with the human body. As a high-performance polymer, silicone possesses several characteristics that make it suitable for medical applications.

○ Firstly, it exhibits excellent biocompatibility, meaning it does not trigger significant immune, toxic, or allergic reactions when in contact with human tissue or bodily fluids. This minimizes harm to patients and ensures safety during medical procedures.

○ Secondly, medical silicone demonstrates exceptional chemical stability, allowing it to withstand exposure to various chemical substances. In complex medical environments, such as those involving disinfectants and medications, it maintains stable performance, ensuring product reliability and longevity.

○ Additionally, medical silicone offers good flexibility, temperature resistance, and ease of processing and molding, fully addressing the diverse needs of the medical field.

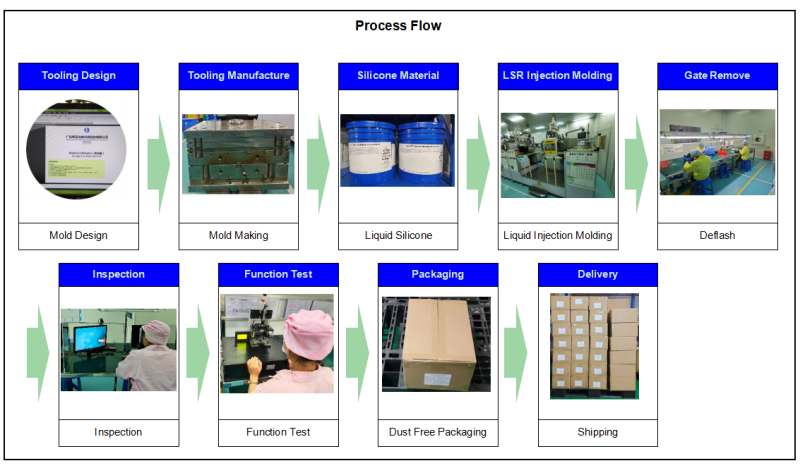

2. Production Process of Medical Silicone Products

The production process for medical silicone products is rigorous and meticulous, with each step critical to ensuring product quality and safety.

◎ Raw Material Preparation

The foundation of this process is the selection of medical-grade silicone raw materials, which must be rigorously screened and tested. These materials must comply with relevant biocompatibility standards or ISO 10993 certification to guarantee product safety from the outset.

◎ Mixing

Silicone raw materials are mixed with various necessary additives in precise proportions. Specific equipment and processes are used to achieve a uniform mixture, fully preparing it for the subsequent molding stage.

◎ Molding

Common molding methods include compression molding and LSR (Liquid Silicone Rubber) injection molding. Compression molding is ideal for producing larger, colored items in smaller quantities. In this method, the mixed silicone is placed into a specially designed mold and shaped under high temperature and pressure. LSR injection molding, on the other hand, is suited for silicone products requiring precise dimensions, transparency, and larger production runs, ensuring both accuracy and consistency.

◎ Post-Processing

After molding, the products undergo post-processing procedures, which include trimming burrs, secondary vulcanization, and surface treatment. These steps ensure that the products meet the stringent standards required for medical use.

3. Application Fields of Medical Silicone Products

Medical silicone products have a wide range of applications, spanning nearly every area of the medical industry. Here are some medical silicone parts YEJIA has manufactured.

★ Eyewash Silicone Components

In eyewash stations, silicone components ensure excellent sealing performance to prevent leakage of the eyewash solution. Additionally, their soft texture minimizes the risk of secondary damage to the eyes, providing safe and effective flushing for patients with eye injuries.

★ Medical Test Kits

Silicone valves for medical test kits effectively protect reagents from environmental factors, preventing volatilization and deterioration. This ensures the stability and accuracy of the reagents, thereby enhancing the reliability of test results.

★ Medical Negative Pressure Ball

The medical negative pressure ball utilizes the flexibility and elasticity of silicone to generate stable negative pressure, facilitating medical procedures such as wound drainage. This helps patients expel fluid and blood from wounds, promoting healing.

★ Pelvic Training Instrument

In pelvic training instruments, silicone sleeves conform to the body's contours, providing comfortable support and a better training experience. Their excellent elasticity ensures accuracy and stability in training outcomes.

★ Medical Testing Equipment

Silicone optical components in medical testing equipment offer high light transmittance and superior optical properties, ensuring accurate signal transmission. This improves the precision of test results and provides a reliable basis for disease diagnosis.

★ Dry Eye Treatment

For patients with dry eyes, silicone eye masks or treatment devices provide gentle stimulation and protection, alleviating discomfort such as dryness and pain while improving the eye's environment.

★ Medical Reagent Applications

Silicone valves and sealing rings in medical reagents accurately control reagent flow, preventing leakage and contamination. This ensures the safety of reagents during storage and use.

4. Advantages of YEJIA in Producing Medical Silicone Products

◆ Extensive Production Experience

YEJIA has over 15 years of production experience, accumulating a deep technical foundation and rich industry expertise. This extensive background enables us to effectively address complex production needs, swiftly resolve issues that arise during manufacturing, and maintain a stable product supply.

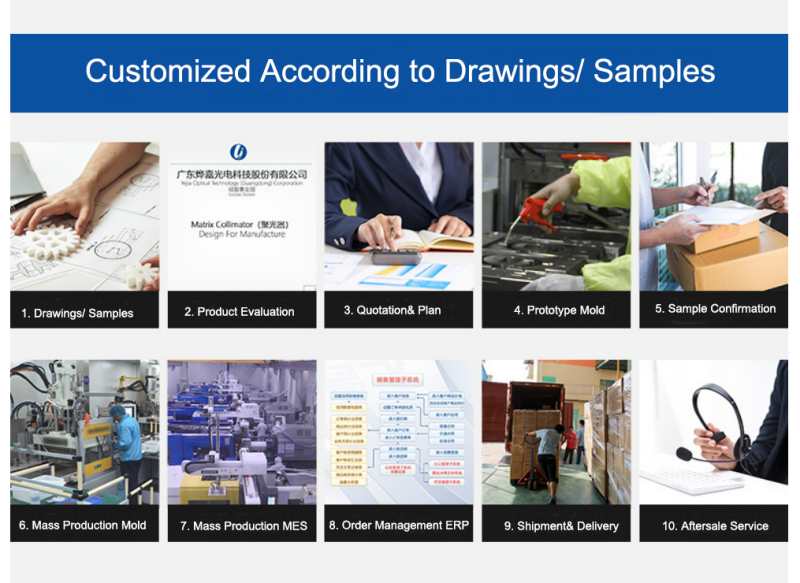

◆ In-house Mold Design and Manufacturing

YEJIA features independent departments for mold design and manufacturing, ensuring a seamless transition from product design to mold creation. This integrated approach not only shortens the production cycle and enhances efficiency but also allows for better quality control of molds, ensuring product accuracy and consistency.

◆ International Engineering Team

YEJIA is supported by an international team of engineers from China, Japan, and South Korea, bringing together diverse expertise and innovative thinking. This collaboration fosters continuous technological advancement and innovation, helping us maintain an industry-leading position in performance and quality.

◆ High-Quality Collaboration Resources

YEJIA cooperates with Fortune 500 companies, which serves as a testament to our product quality and production capabilities. These partnerships provide opportunities for knowledge exchange with top international firms, keeping us informed about the latest industry trends and market demands, thereby enhancing its competitiveness.

◆ Rigorous Quality System Certification

YEJIA has achieved certifications such as ISO 9001, ISO 14001, ISO 1385, and IATF 16949. These certifications reflect our robust quality management system, standardized environmental practices, and adherence to international standards in occupational health and safety, particularly within the automotive industry. The stringent quality control system ensures that every aspect of production, from raw material procurement to final product delivery, meets high standards.

◆ Clean Production Environment

YEJIA operates a 100,000-level clean workshop, providing a highly controlled environment for production. This clean setting effectively minimizes the risk of dust, microorganisms, and other contaminants, ensuring the purity and stability of products, especially those with stringent environmental requirements like medical-grade silicone.

◆ High-Precision Equipment

YEJIA utilize advanced, high-precision mold manufacturing, inspection, and production equipment imported from abroad. This technology ensures precise control over product dimensions and tolerances, enhancing quality stability. Additionally, advanced inspection equipment conducts thorough testing to guarantee that each product meets required standards.

◆ Automated Production and Inspection

YEJIA has implemented automated production and inspection processes, significantly boosting efficiency and product quality consistency. Automation reduces human error and production costs, while automated inspection allows for rapid and accurate testing, ensuring that any non-compliant products are identified promptly.

◆ High-Quality Raw Materials and Strict Testing

The raw materials used comply with ISO 10993 certification or biocompatibility reports and undergo rigorous testing, including pyrogen, skin sensitization, skin irritation, cytotoxicity, and hemosolubility tests. These assessments ensure the safety and biocompatibility of the materials, laying a solid foundation for producing high-quality medical-grade silicone products.

If you require large order volumes with strict demands for product stability and tolerance control, YEJIA is your best choice. With its numerous advantages, we can provide high-quality, reliable, and stable medical silicone products to support your success in the medical field.