Apr. 23, 2025

Helping Clients Capture the ADB Adaptive Headlamp Market and Empowering the Future of Automotive Matrix Lighting

With the growing adoption of ADB (Adaptive Driving Beam) headlamp technology, automotive lighting manufacturers face two major challenges:

1. How to integrate more high-precision light guides within a limited space?

2. How to ensure long-term optical stability under extreme environmental conditions?

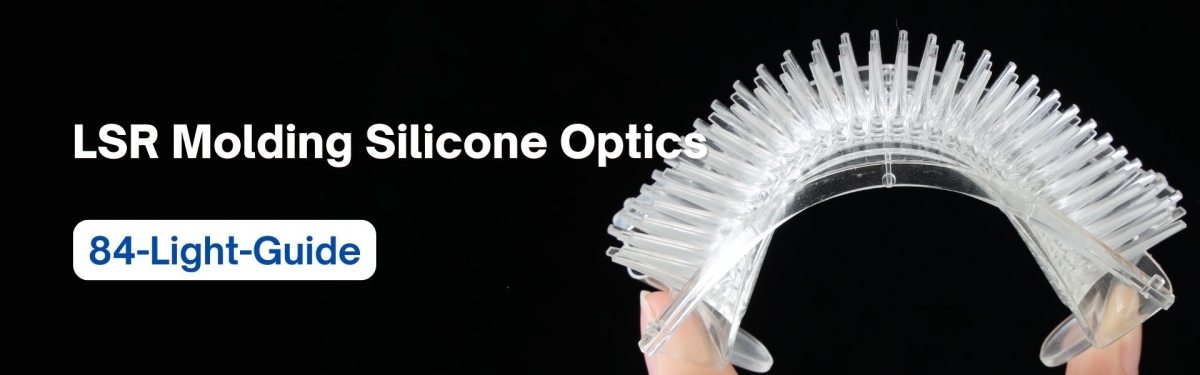

Technical Challenge: The Ultimate Test of 84 light guides with Varying Angles

The light guide silicon lens , as a key optical component, plays a critical role in directing light accurately and controlling beam distribution. Experienced in liquid silicone rubber (LSR) optical parts development, YEJIA successfully developed an 84-light-guide silicon lens for an automotive client—once again proving our technical strength in custom silicone optics solutions.

The core of this silicon lens lies in the design of 84 light guides , each with a unique angle and a long, slender structure. This posed extremely high demands on mold precision, venting systems, and injection control. In LSR molding, the optical performance must maintain clarity while remaining free of bubbles, sink marks, or extra burrs—ensuring light guidance consistency and intensity, as required by advanced automotive lighting systems.

Traditional Manufacturing Faced Three Major Challenges:

1. Structural Complexity: The densely packed light guides required angle tolerances within 0.02mm, making mold design exponentially more difficult.

2. Material Reliability: The optics needed to meet high light transmittance (>92%), flame resistance, and UV aging resistance.

3. Cost-Efficiency Conflict: The multi-light-guide structure significantly increased mold costs, creating a need to balance performance with ROI.

YEJIA's Solution: Tackling Industry Pain Points with an Innovative Tech Chain

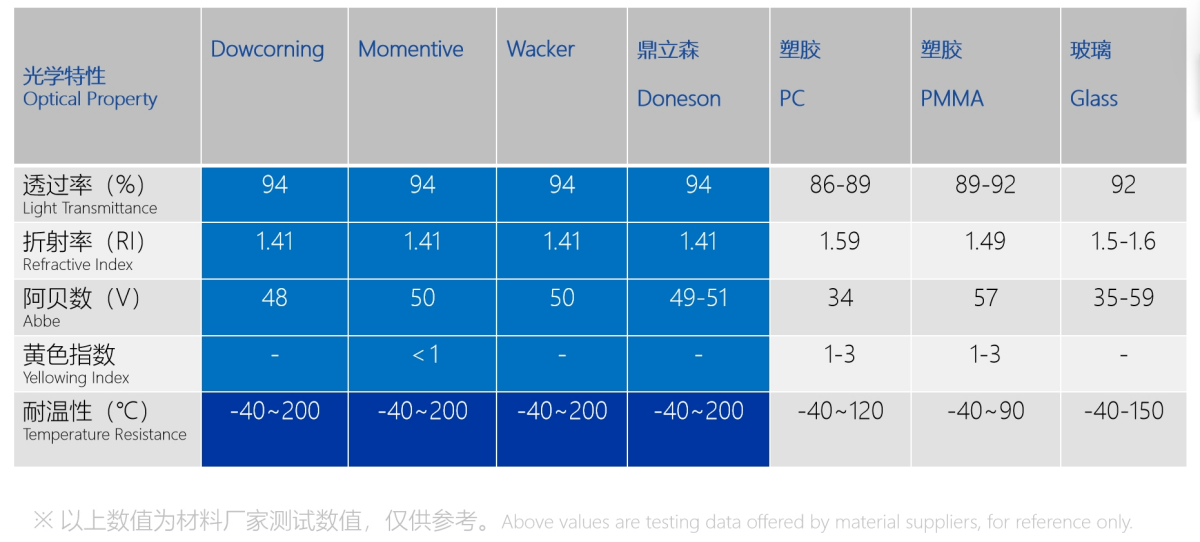

Material Advantage: Ultra-Clear Optical Liquid Silicone Rubber

YEJIA selected Dow Corning MS4002—an ultra-clear LSR material with excellent optical clarity and stability. It maintains performance even in outdoor or high-temperature environments thanks to its heat resistance, UV stability, and anti-yellowing properties. With natural flame resistance and excellent moldability, it's ideal for complex micro-structured optical parts used in automotive, outdoor, and UV lighting applications.

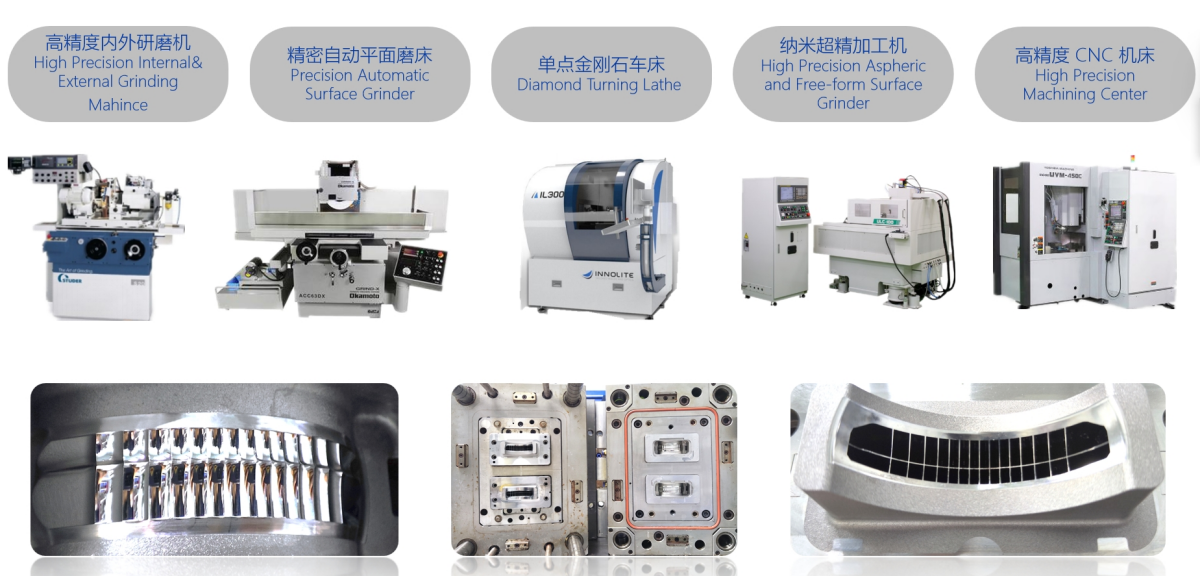

Key to Success: Mold Innovation & Technical Breakthroughs

At the project's onset, our engineering team conducted multiple feasibility studies, mold flow simulations, and structural evaluations. We proposed using YEJIA's proprietary standardized mold base system and suggested developing a shared mold base prototype tool to quickly validate optical performance and structural feasibility—reducing development costs and accelerating progress.

Project Success Factors:

1. Professional mold design and mold flow analysis ensured precision in light guide angles and overall molding quality.

2. Proprietary cold runner system enabled precise LSR injection molding and efficient demolding.

3. Over 50 LSR optical mold projects provided deep technical experience.

4. Standardized mold platforms drastically shortened development time—perfect for new product validation and low-volume trials.

Project Results: Client Recognition and Mass Production Launch

Throughout the project, YEJIA maintained seamless communication with the client and resolved several technical challenges. The final product passed all performance tests and was recognized by the client for its optical consistency, structural accuracy, and molding efficiency—moving smoothly into mass production.

Why Choose YEJIA to Custom Light Guide Silicon Lenses?

As a specialist in custom silicone lenses, YEJIA consistently delivers high-quality solutions for LED, automotive, and UV lighting applications. From material selection and mold design to liquid injection molding, we offer a one-stop LSR molding solution to help clients quickly bring innovative products to market.

— Choose YEJIA: Where Every Beam of Light Reaches the Future with Precision —

Want to learn more about silicone optics, light-guide silicon lenses , or optical-grade silicone applictions? Contact us for a tailored solution!