LSR Molding Silicone Matrix for Automotive ADB Headlights

Dec. 13, 2023

LSR Molding Silicone Matrix for Automotive ADB Headlights

The automotive industry has seen a significant shift towards lens type headlights, with silicone matrix emerging as a promising alternative to traditional materials. While glass optical matrices offer advantages in terms of light transmission and durability, they are also expensive and prone to breakage. The development of PC and PMMA matrices provided a more cost-effective solution, but yellowing remained a concern for automobile manufacturers. The introduction of silicone matrix addressed these issues, offering high light transmission, stability against UV and blue lights, and thermal stability.

Silicone matrix offers several advantages in automotive lighting applications. It has a high light transmission rate of up to 94% and excellent stability against UV and blue lights. This is particularly beneficial for automotive headlights, which use high-power light sources. While new LED systems have low power consumption and high brightness output, they can generate high temperatures, which can accelerate the aging of traditional optical thermoplastic matrices and shorten the LED system's service life. Silicone matrix's physical stability effectively addresses this issue by preventing yellowing.

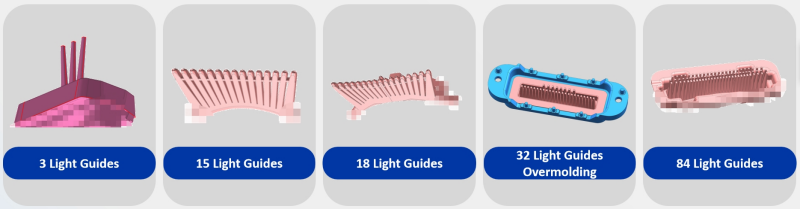

In addition, in the emerging application of Adaptive Driving Beam (ADB) lighting for automotive headlights, LSR molding silicone matrix provides excellent thermal stability and unprecedented design flexibility. Its processing characteristics, optical properties, and hardness enable the production of complex optical products with surface textures similar to traditional optical plastics. These properties are expected to enhance the use of ADB in automotive lighting and empower optical designers to shape the future of automotive lighting.

Furthermore, silicone matrix can easily integrate with other advanced technologies such as LED lighting systems and adaptive lighting systems. This integration enhances the functionality and performance of automotive lighting, ultimately improving safety and comfort for both drivers and passengers.

The use of silicone matrix in the lighting industry has brought about a significant change in the automotive headlights. The unique properties of Optical LSR (Liquid Silicone Rubber) material make it a promising alternative to traditional matrices. Due to its exceptional stability and performance, silicone matrices are expected to gain popularity in ADB automotive headlights in the future.

YEJIA is a leading manufacturer of silicone matrices, specializing in LSR injection molding and silicone over-molding. With extensive knowledge of liquid optical silicone characteristics and experience in processing high precision optical silicone matrices, YEJIA has provided various optical silicone matrices for well-known brands. For more information and to begin the process of customizing silicone matrix, please feel free to reach out to us.