Nowdays, waterproofing has been a hot selling point for smartphones. With the increasing requests of mobile phone quality, the waterproof level is getting higher. Waterproof mobile phone pluger as a tiny part, plays a key role in waterproof cell phones.

Many mobile phone plugers in the market are using sealing o rings to make phones waterproof, because of the instability of processing and performance, more and more cellphone manufacturers prefer the technics of Co-injected.

Yejia Optical Silicone Division, focuses on silicone co-injected with other materials for years, and our engineers are familiar with the characteristics of both silicone and plastic. The production dept. can make the mass production yield over to 90%. With 5 Japanese engineers, over 20 years of experience in designing mold, and our top world mold making equipment, our engineers can ensure the mold precision from the beginning, that is, mold design, so as to lower the defective rate and reduce human costs.

Here we would like to share some common defects and reasons in co-injection while in producing waterproof mobile phone plugers.

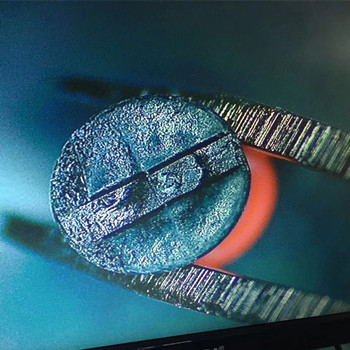

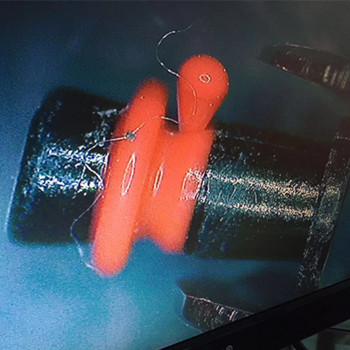

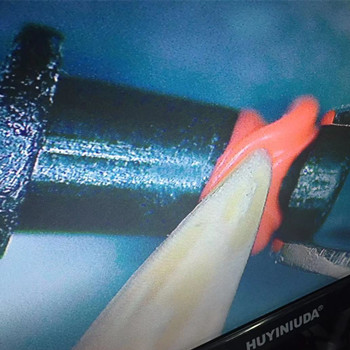

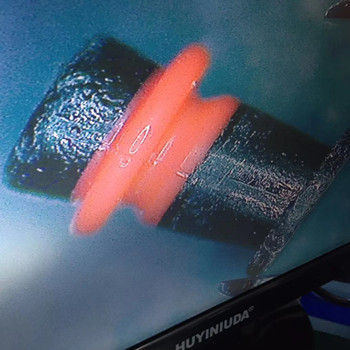

| Defects | Reasons | Images (Inspected by 50 Times Magnifier)

|

| Silicone-Overflowed | Because of the error of plastic sealing size, caused the overflow.

|  |

| Plastic Crushed | Because of the proble in design, the punching position is not accurate. The product is deviated when to be punched, so it gets crushed. |  |

Big Gate Flash

| The gate of silicone mold is too big. |  |

| Short of Silicone | The gate of silicone mold is nonuniform. When producing with the single side mold, the dead mass in the injection nose block the gate.

|  |

Degumming

| There is oil on the plastic. The glue is not applied appropriatedly The molding temperature is too low. The ratio of agent A and agent B is not 1:1.

|  |

| Mold Sticking | There are too much glue on plastic, it will be sticked on mold in injection. The molding temperature is too high.

|  |

| Bubbles | The air venting is not smooth. |  |

For more details, please feel free to contact us. We are looking forward to a technical discussion with you.