How to Choose a High-Quality Silicone Rubber Valve: A 5-Step Guide

Introduction

A silicone rubber valve may be small, but it plays a big role in the performance of food-grade packaging, medical devices, and electronic components. Unfortunately, the market is flooded with products of varying quality. To help you avoid costly mistakes, here's a 5-step guide to evaluating silicone rubber valves based on the most critical performance factors.

1. Use of Food-Grade or Medical-Grade Raw Materials

High-quality valves are made from liquid silicone rubber (LSR) that meets FDA, LFGB, and ISO 10993 standards. These materials offer:

Avoid: Recycled or industrial-grade silicone which may contain impurities and pose safety risks.

2. High-Precision Molding Process

Premium valves are produced using LSR injection molding or compression molding with high-tolerance tooling. This ensures:

Low-end valves often suffer from poor sealing and dimensional inaccuracies due to subpar molds or uncontrolled processes.

3. Clean Flash Removal for Better Sealing

Flash—excess silicone material along the edges—must be precisely removed. Top-tier products undergo automated die-cutting for clean, smooth edges that enhance both function and appearance.

Poor trimming can lead to sharp edges, leakage, or failure during long-term use.

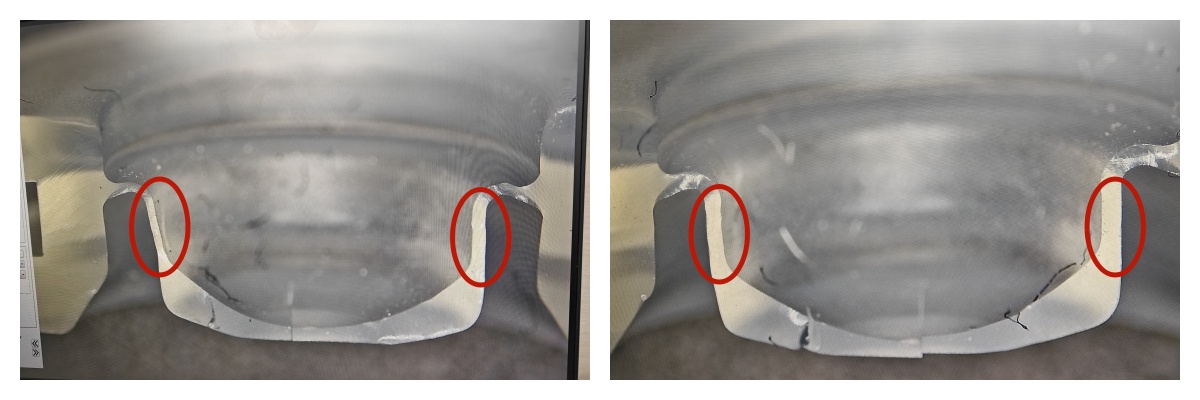

4. Uniform Wall Thickness for Optimal Durability

Wall thickness directly impacts valve longevity and flexibility. Premium valves maintain thickness tolerance within ±0.05mm, ensuring balanced performance.

Test by:

5. Precision-Cut Slits for Accurate Flow Control

The slit is the working core of any silicone rubber valve. High-end valves use automated, precision die-cutting to create complete, clean, centered slits with:

Avoid: Hand-cut or misaligned slits that leak or dispense erratically.

Why Choose Yejia for Silicone Rubber Valves?

With over 15 years of experience, Yejia Optical Silicone Division delivers unmatched precision in custom silicone rubber valve manufacturing. Our valves feature:

✅ Cross slits with zero gap

✅ 24/7 leak-proof testing

✅ 100% dispensing reliability

✅ ±0.3mm slit tolerance

✅ ±15° flow control angle

✅ Uniform wall thickness

✅ Centered, non-sticky slits

Contact us today to get samples or learn more about our manufacturing capabilities.